Ever had that sinking feeling? You've just spent ages washing a car, it looks perfect while it's wet, but as it dries, those infuriating white spots and a hazy film start to appear. It’s not down to your technique or the products you're using—it's the ghost of your tap water.

To get that truly flawless, spot-free finish every single time, you have to tackle the water itself. Filtering it to remove the dissolved minerals that cause these marks is the secret professional valeters have known for years. It's how they deliver that showroom-quality shine, consistently.

Why Your Tap Water Is Sabotaging Your Car Washes

It’s a classic story for anyone who takes pride in their work. You wash, polish, and stand back to admire the gleam, only to see it ruined by tiny, stubborn water spots once it's dry. This isn't on you; the problem is literally baked into the water coming out of your hose.

The main culprits are minerals like calcium and magnesium, which are especially common across the UK's water supply. We measure the concentration of these invisible minerals as Total Dissolved Solids (TDS). When a bead of tap water evaporates off the paintwork, the H₂O goes, but it leaves every speck of that mineral deposit behind.

The Science Behind a Perfect Spot-Free Rinse

That chalky residue is what creates those white spots that are such a pain to buff out. It’s not just that they look bad; over time, these mineral deposits can actually etch into the clear coat, causing permanent damage to a vehicle's paintwork.

For any serious detailer or car wash operator, getting a handle on TDS isn't just a nice-to-have, it’s a core part of the job. It’s what separates an 'okay' clean from an exceptional one. The aim of the game is to get that TDS reading down as close to zero as you possibly can, and that's where proper water filtration comes in.

When you use purified water for the final rinse, you're guaranteeing that nothing is left behind on the surface. This one change completely eliminates the need to rush around with a drying towel, which is often where you risk putting fine scratches and swirl marks back into the paint you just perfected.

The Professional's Approach to Pure Water

Getting water this pure means going far beyond what your tap can provide. In the professional world, two technologies are considered the gold standard for producing water clean enough for that perfect finish:

- Reverse Osmosis (RO): This is the workhorse. RO systems force water through a special membrane that strips out the vast majority of minerals and other contaminants.

- Deionisation (DI): Think of this as the finishing touch. A DI system uses a specialised resin to grab any tiny ions the RO system might have missed, bringing the TDS right down to 0 ppm for a guaranteed spot-free rinse.

Using untreated water is the root cause of so many problems, like figuring out how to remove hard water stains from windows—an issue a good filtration setup prevents from happening in the first place.

If you're ready to explore this further, our in-depth guide to https://24purewater.co.uk/car-cleaning/ is packed with practical advice. At the end of the day, investing in the right water system isn't just an expense; it's a direct investment in the quality of your work, your efficiency, and your customers' happiness.

Getting Your Water Filtration Right: A Valeter's Guide

Walking into the world of water filtration can feel a bit like learning a new language. You're hit with a barrage of acronyms—RO, DI, TDS—and it’s easy to get bogged down in the technical jargon. Let's cut through that noise and talk about what these systems actually do for your business, and more importantly, in what order you should be using them.

Think of it like detailing a car. You wouldn't start with a final polish before you've washed and decontaminated the paintwork. The same logic applies here. Each stage of filtration has a specific job, preparing the water for the next, more sensitive process. Get the order right, and you'll get flawless results while protecting your investment.

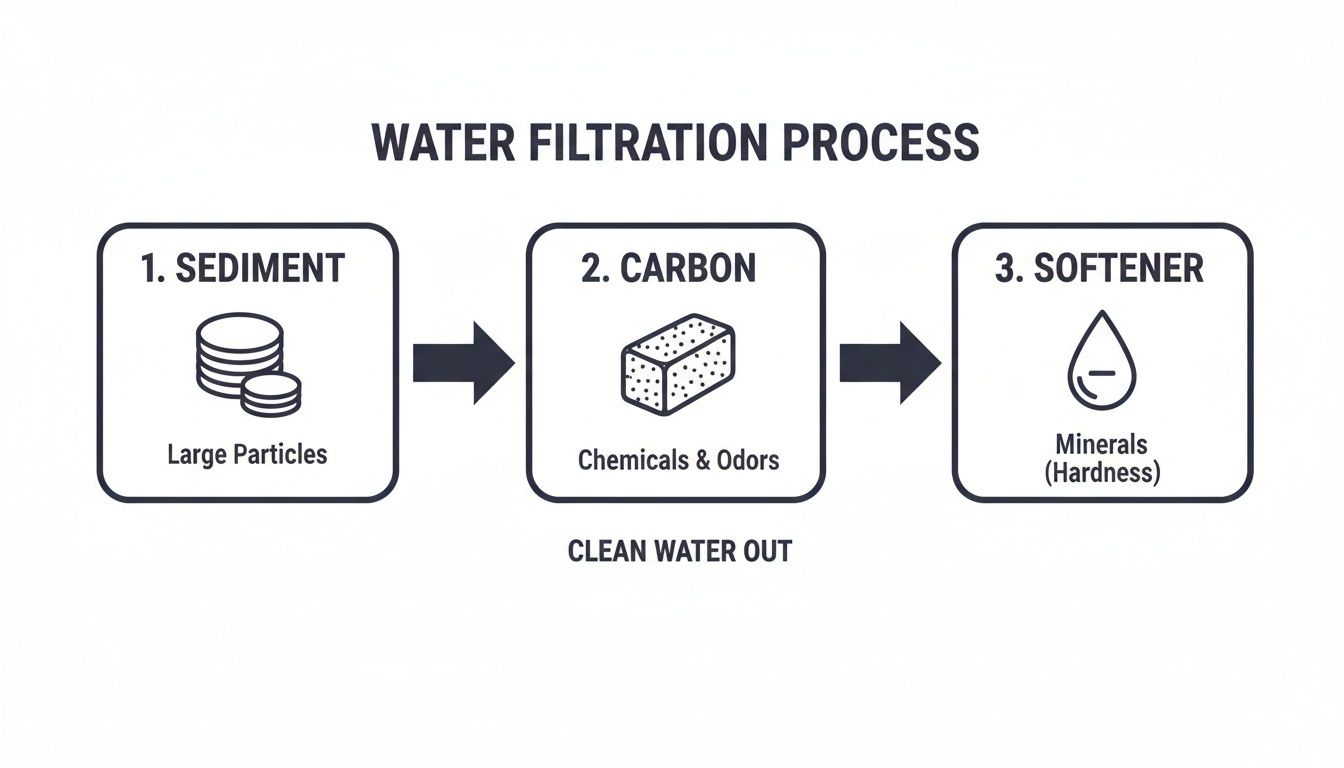

The Gatekeepers: Sediment and Carbon Filters

Before you can even dream of a spot-free rinse, you need to tackle the basics. Your first two lines of defence are there to protect both the car's finish and the more expensive filtration gear that comes later.

-

Sediment Filters: This is your non-negotiable starting point. A sediment filter is a simple physical screen that catches the big stuff—sand, silt, rust flakes, and any other grit lurking in the mains supply. Skip this, and you're asking for trouble. That debris will block your jet wash nozzles, scratch paintwork, and grind away at the internals of your pumps and other filters.

-

Carbon Filters: Right after the sediment filter, your water should hit a carbon filter. Its main job is to pull out chlorine and chloramines, the chemicals water companies use to keep the supply safe. While great for public health, chlorine is bad news for cars. It can dull paint over time, break down waxes and sealants, and absolutely wrecks the delicate membranes in a reverse osmosis system.

These two are the unsung heroes of your setup. They’re cheap to buy and maintain, but they're critical for the health and performance of everything else downstream.

Dealing with Hard Water: The Role of a Water Softener

Once the grit and chlorine are gone, the next big problem for most of the UK is water hardness. If you’ve ever seen those stubborn white spots on a car, you’re looking at the calling card of calcium and magnesium—the minerals that make water 'hard'.

A water softener tackles this head-on using a process called ion exchange. Inside, a tank full of resin beads grabs those hard mineral ions and swaps them for 'soft' sodium ions.

Here's the key thing to understand: A softener doesn't purify the water like an RO or DI system does. It just swaps one mineral for another. Your Total Dissolved Solids (TDS) reading will stay about the same. But what it does do is stop limescale in its tracks, which makes soaps lather up beautifully and, crucially, acts as a bodyguard for your most expensive equipment.

Placing a water softener directly before a Reverse Osmosis unit is one of the smartest moves you can make. It prevents hard minerals from crystallising on the RO membrane and clogging it up, which will save you a fortune in premature replacement costs.

To give you a better idea of how these technologies stack up, here’s a quick comparison.

Comparison of Car Wash Water Filtration Technologies

Choosing the right system means matching the technology to your specific water quality and desired results. This table breaks down the most common options to help you decide where to invest.

| Filtration Technology | Primary Purpose | Effectiveness (TDS Removal) | Typical Upfront Cost | Ongoing Maintenance |

|---|---|---|---|---|

| Sediment Filter | Removes physical particles (sand, rust, silt) | 0% (removes undissolved solids) | Low | Replace cartridges regularly |

| Carbon Filter | Removes chlorine, chloramines, odours | 0% | Low | Replace cartridges regularly |

| Water Softener | Exchanges hard minerals (calcium, magnesium) for sodium | 0% (TDS remains similar) | Medium | Replenish salt blocks/pellets |

| Reverse Osmosis (RO) | Removes the vast majority of dissolved solids | 95-99% | High | Membrane replacement (every 1-3 years) |

| Deionisation (DI) | Removes the final remaining ions for pure water | Up to 100% (achieves 0 ppm) | Medium-High | Replace DI resin when exhausted |

Ultimately, a multi-stage approach combining several of these technologies is the professional standard. You start with basic filtration to protect your gear and finish with high-purity systems to guarantee a flawless result for your customers.

The Spot-Free Finishers: Reverse Osmosis and Deionisation

With your water now clean, clear, and soft, it's time for the final push to get that perfect, spot-free finish. This is where the heavy hitters, Reverse Osmosis (RO) and Deionisation (DI), step in.

Reverse Osmosis (RO): Think of RO as the workhorse of water purification. It uses a powerful pump to force water through a very fine, semi-permeable membrane. This membrane acts like a microscopic sieve, allowing pure water molecules to pass through while blocking 95-99% of all the dissolved minerals and contaminants. The pure water (known as permeate) heads to a storage tank, ready for use, while the concentrated waste (brine) is flushed down the drain.

This technology is the foundation of any professional spot-free rinse system. The demand for this level of purity is growing; the UK's water purification market is expanding as both businesses and consumers become more aware of water quality issues. In fact, modern RO systems can remove up to 99% of contaminants while reducing wastewater by over 80% compared to older, less efficient designs. You can read more about the UK's water purification market trends to see where the industry is heading.

Deionisation (DI): If RO is the workhorse, DI is the final polisher. It’s the specialist that takes very clean water and makes it absolutely perfect. After the RO system has done the heavy lifting, the water passes through a DI vessel filled with a special mixed-bed resin. This resin acts like a magnet for any last remaining charged ions that slipped past the RO membrane.

This is the final step that takes your water's TDS from a low number (say, 5-20 ppm post-RO) down to an immaculate 0 ppm. This is the secret sauce. Water this pure has nothing left in it to leave behind when it evaporates, guaranteeing a truly spot-free finish without ever touching the car with a drying towel.

Building Your Ideal Car Wash Filtration System

Moving from theory to practice is where the rubber really hits the road. Designing a filtration system for your car wash isn't just about ticking boxes and buying parts; it's about building a cohesive setup that works for your specific operation. A properly designed system saves you a fortune in the long run and gives you those flawless, spot-free finishes. Get it wrong, and you're in for a world of constant frustration.

The first thing you absolutely must do is figure out your actual water demand. This isn't a ballpark guess. It's a hard calculation based on your gear and how you work. You need to know your pressure washer's flow rate, measured in litres per minute (LPM).

Let's say a typical professional pressure washer pushes out 15 LPM. If you've got two detailers working flat out, your peak demand is 30 LPM. Your filtration system has to handle that flow comfortably. If it can't, you'll see a massive pressure drop, and your equipment will feel weak and ineffective.

Measure Twice, Build Once

Before you spend a single penny on filters, you need two critical bits of information about your water supply: its pressure and its purity.

- Mains Water Pressure: Get a simple pressure gauge that screws onto an outdoor tap. If your pressure is low (under 2.5 bar or 40 PSI), you might need to factor in a booster pump, especially if you plan on running a reverse osmosis system.

- Total Dissolved Solids (TDS): A handheld digital TDS meter is a cheap and non-negotiable tool. Test your tap water to get a baseline reading in parts per million (ppm). This number will tell you what kind of system you need and, crucially, how fast you'll burn through consumables like DI resin.

Knowing these two figures will save you from making very expensive mistakes. There’s no point dropping thousands on a high-flow RO system if your mains pressure can't even get the water through it.

The Correct Sequence for Flawless Filtration

The order your filters are in is non-negotiable. Get this wrong, and you can wreck expensive parts and get terrible results. The logic is simple: each stage is there to protect the next, more sensitive (and more expensive) stage down the line.

This diagram shows the fundamental flow for pre-treating your water before it even gets close to the high-purity stages.

As you can see, each filter has a specific job, prepping the water so the next stage can work efficiently and the whole system lasts as long as possible.

For a full professional setup, the sequence always looks like this:

- Stage 1: Sediment Filter: This must always come first. It’s your front line, catching the grit, rust, and sand that would clog up everything else.

- Stage 2: Carbon Filter: Next, the carbon filter takes out chlorine. Chlorine will absolutely destroy an RO membrane, so this stage is vital.

- Stage 3: Water Softener: Positioned after the carbon, the softener removes calcium and magnesium—the minerals that cause limescale. This is essential protection for the RO membrane, stopping scale from building up and killing it.

- Stage 4: Reverse Osmosis (RO) System: Now the pre-treated water hits the workhorse. The RO unit forces water through a fine membrane, removing up to 99% of the remaining TDS.

- Stage 5: Deionisation (DI) Vessel: This is your final polishing stage. The super-clean water from the RO system flows into the DI vessel, which strips out the last few remaining ions to produce perfect, 0 ppm water.

Never, ever run hard tap water directly into a DI vessel. You will exhaust the resin in a shockingly short amount of time, making it an unbelievably expensive way to get pure water. A DI vessel is designed to polish already clean water, not treat raw tap water.

Avoiding Common System Design Pitfalls

When setting up your filtration, it’s the small oversights that cause the biggest headaches later on. Let’s walk through a real-world scenario to show why sizing is so important.

Imagine a mobile valeter, Mark, who buys a small DI vessel rated for a maximum flow of 10 LPM. The problem? His pressure washer runs at 15 LPM. By pushing water through the vessel faster than it was designed for, he’s creating a big problem.

This high flow rate reduces the "contact time" the water has with the resin beads, meaning the ion exchange process can't happen properly. As a result, mineral ions slip right through, his final TDS reading starts to creep up, and he sees water spots on his final rinses. Mark is burning through expensive resin far faster than he should be, all while getting poor results.

The fix was simple: either throttle back the pressure washer flow during the final rinse or, better yet, upgrade to a larger DI vessel rated for his equipment's output. A simple mistake of undersizing one component undermined his entire investment.

Keeping Your System Running: Installation and Long-Term Care

Having a top-notch water filtration system is a great start, but it’s only as good as its installation and maintenance. Get the setup right from day one, and you’ll save yourself a world of pain down the line. A simple, consistent maintenance routine is what keeps your water pure, your results professional, and your running costs in check.

Let’s get into the practical side of things—how to set up your system and look after it for the long haul.

First up, location. You need a spot with easy access to your mains water supply and a drain. It’s also got to be protected from frost. The biggest mistake I see is people cramming systems into tight corners; make sure you leave plenty of room around the filter housings and vessels. You’ll thank yourself later when you’re not wrestling to unscrew a housing in a cramped space.

Getting the Plumbing Right

A little plumbing know-how goes a long way here. Most filtration gear in the UK uses British Standard Pipe (BSP) threads, so just make sure any fittings you buy match up.

Here’s a pro tip: install a bypass loop. This is just a simple three-valve setup that lets you send water around the filtration system instead of through it. It’s a lifesaver. When you need to change a filter or do some maintenance, you can just bypass the system and keep the water on for everything else. No need to shut down your entire operation for a five-minute job.

Your Essential Maintenance Checklist

With water systems, consistency is everything. Sticking to a simple schedule prevents those sudden drops in water quality and, crucially, protects the expensive bits like your reverse osmosis membrane from premature failure.

Here’s a straightforward routine that works:

- Sediment & Carbon Filters: These are your workhorses. I’d recommend checking them every 1-3 months. If they look grubby or you notice the water pressure dropping, it’s time for a change. If you’re in an area with particularly sludgy water, you might be doing this a bit more often.

- Water Softener Salt: The only job here is to keep the brine tank topped up with salt. A quick glance once a week is all it takes. Whatever you do, don't let it run empty. If it does, the softener won't regenerate, and you'll be sending hard water straight into your RO system, which is a big no-no.

- DI Resin: The lifespan of your DI resin is a guessing game without data. It all depends on the TDS of the water coming from your RO. The only way to know for sure is to test the final output with a handheld TDS meter. Once that reading starts to creep up from a perfect 0 ppm to around 5-10 ppm, it’s time to swap out the resin.

By the time you can actually see water spots on a vehicle's paintwork, your DI resin is long dead. The only way to guarantee a flawless, spot-free finish every single time is to be proactive and test with a TDS meter.

Telltale Signs That a Replacement is Due

Your system will give you little warnings before a major component gives up. Learning to spot them early will save you from bigger headaches.

The classic sign of a dying RO membrane is a slow, steady increase in the TDS reading of the water it produces (that's before it gets to the DI stage). For example, if your RO used to put out water at 15 ppm but now it’s consistently hitting 30-40 ppm, it's losing its filtering power. This forces your DI resin to pick up the slack, meaning you’ll burn through it much faster. When you see those numbers climbing, it's time to start budgeting for a new membrane.

Common Problems and Quick Fixes

Even the best-maintained systems have off days. Knowing how to quickly diagnose the common culprits will save you time, money, and a lot of frustration.

Problem: The pressure washer feels weak, and flow has dropped off.

This is almost always a clogged pre-filter. It’s the first and most common bottleneck.

- Solution: Pop open the first housing and check your sediment filter. Nine times out of ten, replacing this will solve the issue. If it’s still low, the carbon filter is your next suspect.

Problem: TDS readings have suddenly shot up.

If you’re suddenly getting high TDS readings from your pure water tap, the problem lies with your DI stage.

- Solution: First, double-check that your flow rate isn't too high. If water rushes through the DI vessel too quickly, the resin can't do its job properly. If the flow rate is fine, it’s a clear sign your DI resin is spent and needs replacing.

Why Bother with Pure Water? The Business Case Explained

Thinking about upgrading your water supply? Let's be clear: this isn't just a technical fix for those annoying water spots. It's one of the smartest business decisions a car wash or valeting service can make. When you invest in a proper system to filter water for car wash use, you'll see a real-world return that strengthens your bottom line, builds your reputation, and makes your entire operation run smoother.

The most obvious win is getting your team's time back. Just think about how many hours are wasted meticulously hand-drying every single vehicle, chasing down drips, and buffing out streaks left by hard tap water. It's frustrating, repetitive work that doesn't actually add value.

Switch to a spot-free rinse with deionised water, and that whole drying stage basically disappears. A vehicle can be left to air-dry and the finish will be perfect. You can then use those reclaimed hours for jobs that make you money—think polishing, interior detailing, or simply getting more cars through the wash bay. Your daily revenue potential goes up immediately.

Charge What You're Worth and Keep Customers Coming Back

A consistently flawless, spot-free finish is what separates you from the competition down the road. It becomes your calling card. Customers really do notice that superior quality, and they're often happy to pay a bit more for a service that guarantees a far better result than they could ever get at home or at a budget wash.

This is how you build a rock-solid reputation. Word gets around fast when you're known as the place that delivers a perfect finish, every single time. That word-of-mouth marketing translates directly into loyal customers and a stronger, more profitable client base that trusts you with their vehicle. While we focus on cars, using ultrapure water is a mark of quality in many important industries that rely on its quality.

Investing in pure water filtration isn’t just another overhead. It’s a direct investment in your brand's promise of quality. It’s what makes you the go-to expert for car owners who care, rather than just another car wash.

Staying Compliant and Slashing Your Bills

Beyond the shine, there’s the serious business of environmental regulations here in the UK. The car wash industry is huge, washing over 193 million cars a year and generating more than £1 billion in market value. All that activity produces a massive amount of wastewater, which is tightly controlled. Businesses have to follow the Environment Agency's Pollution Prevention Guidelines (PPG 13), which lay out specific rules for water treatment. It’s why so many operators are now looking at water recycling systems.

This is where a good filtration setup pulls double duty. By pairing a quality filtration system with a water reclamation loop, you can solve two problems at once. First, you guarantee that any water you do discharge is legally compliant, protecting you from hefty fines and legal trouble.

Second—and this is a big one—you slash your running costs. By treating and reusing your water, you drastically cut down on how much you draw from the mains and, in turn, reduce your trade effluent bills. What starts as a compliance task quickly becomes a smart way to save money, turning a regulatory headache into a tangible financial win for your business.

Onsite Filtration vs. Buying In Deionised Water

For some valeting businesses, installing a full-scale filtration system just isn't the right move. An increasingly common alternative is to simply buy in pre-filtered deionised water. This offers a different route to getting that perfect, spot-free finish without the initial setup.

The biggest draw is the minimal upfront investment. You completely sidestep the hefty cost of buying and plumbing in RO systems, softeners, and DI vessels. On top of that, you can forget all about maintenance headaches—there are no filters to change, no salt to lug about, and no resin to replace.

Weighing Up the Costs and Convenience

Of course, that convenience comes at a price. The long-term cost per litre is significantly higher when you're buying water, and for a busy operation, that can really add up over a year. You also have the practical challenge of storing intermediate bulk containers (IBCs) and scheduling deliveries, which isn't always straightforward.

For mobile detailers, or anyone working from a site where a permanent installation is a non-starter, this model often becomes a practical necessity. Many find that using readily available ultra-pure water filling stations provides a brilliant, flexible compromise.

The choice really boils down to a break-even analysis. You need to sit down and calculate your monthly water usage, then compare the per-litre cost of buying in water against the amortised cost of owning and running your own filtration system.

The global market for car wash water filter systems is booming, expected to hit £1.7 billion by 2032. This is driven by operators just like you looking for better efficiency and long-term cost savings. Investing in your own onsite filtration system puts you right in line with this trend, giving you ultimate control and better profits down the line. You can learn more about the growth in the car wash water filter market to see where the industry is heading.

Your Questions, Answered

When you're thinking about filtering water for your valeting business, a few questions always pop up. Let's get them answered with some straight, practical advice from years of experience in the field.

If I've Got an RO System, Do I Really Need a Water Softener Too?

In a word, yes. If you’re in one of the UK's hard water areas, you absolutely do. Think of the water softener as the essential bodyguard for your reverse osmosis (RO) membrane. That membrane is the single most expensive part of your whole setup, and you need to protect it.

A softener tackles the calcium and magnesium—the minerals that cause limescale—before they ever reach the RO. Without it, those minerals will quickly build up and permanently clog the microscopic pores in the membrane. Adding this simple pre-treatment step will massively extend the life of your RO membrane, saving you a fortune on early replacement costs and keeping the whole system running as it should.

What's the Real Difference Between Reverse Osmosis and Deionisation?

It’s less about which one is "better" and more about how they work together as a powerful two-stage team.

-

Reverse Osmosis (RO): This is the real workhorse. It uses high pressure to force water through an incredibly fine membrane, physically removing 95-99% of all dissolved solids. It does the heavy lifting, getting your water from tap quality to almost perfectly pure.

-

Deionisation (DI): Think of this as the finishing touch, the final polish. After the RO system has taken out nearly everything, the water then passes through a special deionising resin. This resin acts like a magnet, grabbing the last handful of ions that the RO membrane missed. This is what gets you to that perfect 0 TDS (Total Dissolved Solids) reading, which is the secret to a guaranteed spot-free rinse.

For the absolute best results and lowest running costs, you should always have your DI stage running after the RO system.

The most cost-effective professional setup always uses reverse osmosis to get the water almost perfect, then uses deionisation as the final, crucial step to polish it to zero TDS.

How Often Will I Be Changing My DI Resin?

Honestly, it all comes down to two things: how much water you're pushing through it, and the quality of the water feeding it in the first place. If you're feeding it with super-clean water from a well-maintained RO unit, that resin is going to last you a very long time.

On the other hand, if you tried to run hard tap water straight through a DI vessel, the resin would be completely spent in no time. It would be an incredibly expensive way to get pure water. The only way to know for sure when it's time for a change is to keep an eye on the output with a handheld TDS meter. As soon as that reading starts to creep up past 0 ppm, it’s time to swap it out.

Ready to skip the hassle of onsite filtration and get ultra-pure water whenever you need it? With 24 Pure Water, you get access to a UK-wide network of self-service filling stations. It's a convenient and affordable way to guarantee a perfect, spot-free finish every time. Find your nearest station and start filling today at https://24purewater.co.uk.