Industrial water purification systems aren't just about 'cleaning' water; they're mission-critical processes that protect product quality, safeguard multi-million-pound equipment, and ensure UK businesses stay on the right side of regulations. Think of them as the unsung heroes of modern manufacturing, working behind the scenes to remove specific impurities and keep entire facilities running smoothly.

Why Industrial Water Purification Is Critical

If you picture a factory as a living organism, its water purification system is the kidneys. Just as our bodies need to filter out waste to stay healthy, a factory needs to remove contaminants from its water supply. Without it, things like minerals, bacteria, chemicals, and tiny particles can wreak havoc.

This is a world away from producing drinking water. We're talking about engineering water for a very specific job. The water needed to make a delicate microchip is completely different from the water used to cool heavy machinery or mix a soft drink. Even your standard tap water is full of dissolved solids that can cause massive headaches in an industrial setting.

The Hidden Costs of Untreated Water

Ignoring water quality is a huge gamble. The problems often brew under the surface, only showing themselves when a major failure brings everything to a grinding halt, forcing expensive downtime and emergency repairs.

Here are the main challenges you face with untreated water:

- Equipment Damage: Minerals like calcium and magnesium form limescale inside pipes, boilers, and heat exchangers. This chokes efficiency, drives up energy bills, and can eventually lead to catastrophic equipment failure.

- Product Contamination: In sectors like pharmaceuticals or food and beverage, even the tiniest impurities can ruin product safety, consistency, and shelf life. This often means entire batches have to be thrown away.

- Regulatory Non-Compliance: UK businesses have to meet strict environmental and health standards. Discharging poorly treated wastewater or using non-compliant water in your process can lead to hefty fines and serious damage to your reputation.

Think of an industrial water purification system as a long-term investment in operational stability. It’s about proactive control, stopping problems at their source—impure water—before they turn into costly emergencies.

A Foundation for Quality and Efficiency

At the end of the day, controlling water purity means controlling your outcomes. When a manufacturing process demands a specific water quality, any small change can affect everything from the gloss on a freshly painted car to the effectiveness of a life-saving drug. The required purity can be mind-boggling; to get a sense of the gap between tap water and what industry uses, it helps to understand ultrapure water, which is not your typical drinking water.

By putting the right industrial water purification systems in place, a business isn't just buying a piece of kit. It's laying the groundwork for consistent quality, better efficiency, and long-term resilience. It's simply a non-negotiable part of any modern, competitive industrial operation.

Exploring the Core Purification Technologies

At the heart of any effective industrial water purification system, you'll find a set of powerful, science-backed technologies. Each one is a specialist, designed to tackle specific types of impurities. They often work together, like a team of experts, to achieve the exact water quality a particular job demands. Getting to grips with these core methods is the first step to understanding how a truly customised solution is built.

Believe it or not, the concept of industrial-scale filtration isn't new. In the UK, its roots go back to landmark public health laws like the Metropolis Water Act of 1852, which made filtering London's water supply mandatory. The invention of automatic pressure filters by 1899 was another leap forward, accelerating the ability to force water through purification media—a principle that still underpins many systems today.

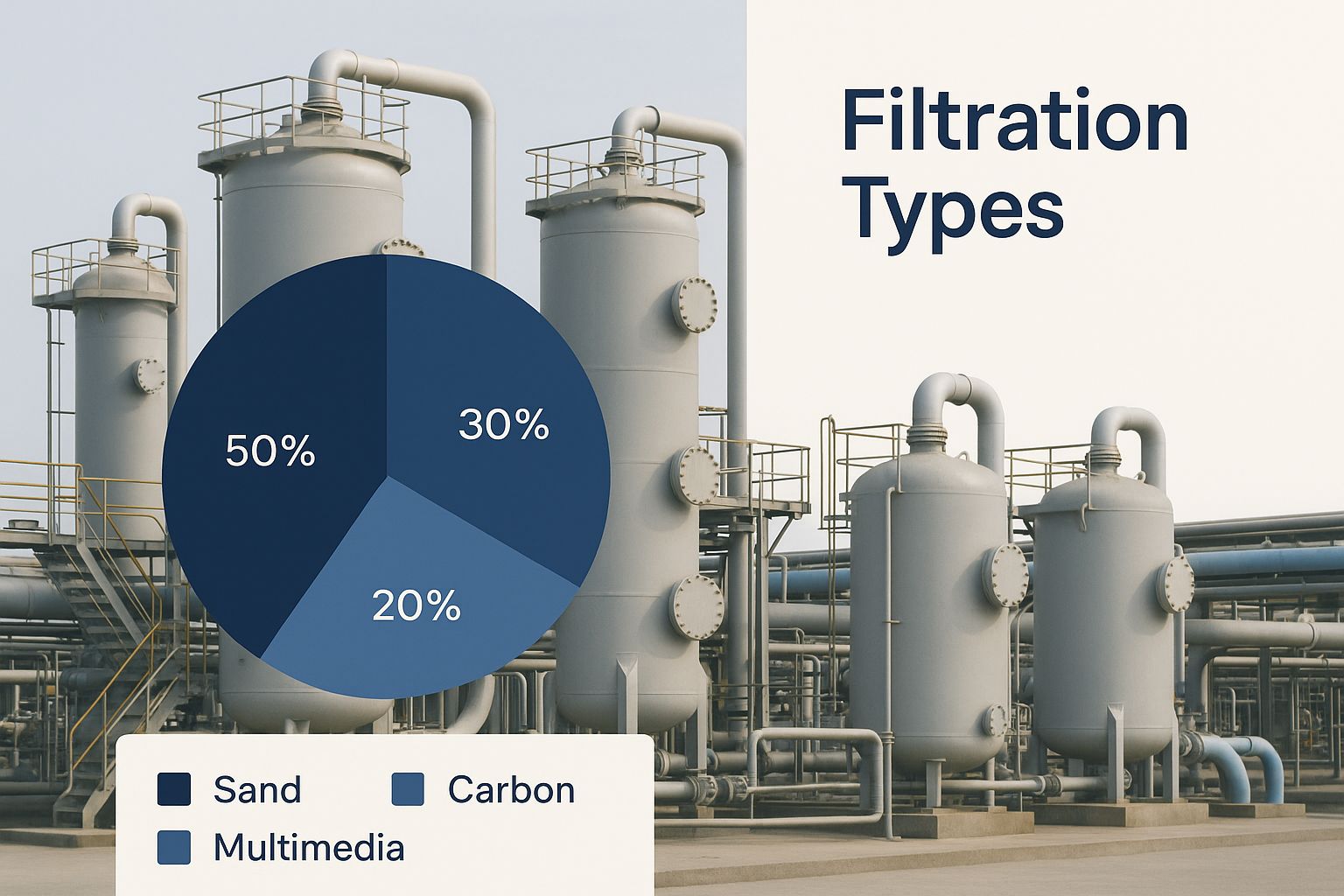

This image gives a great high-level overview of the different filtration categories used across various industries.

As you can see, it's often a layered approach, with different filtration types working in sequence to achieve the purest possible result.

To help make sense of it all, let's take a look at the most common technologies you'll encounter. Each has its own strengths and is best suited for particular challenges.

Comparison of Key Water Purification Technologies

This table compares the primary functions, advantages, and ideal use cases for the most common industrial water purification technologies.

| Technology | Primary Function | Removes | Best For |

|---|---|---|---|

| Reverse Osmosis (RO) | Molecular-level filtration under pressure. | Dissolved salts, minerals, heavy metals, larger organic molecules. | Desalination, boiler feed water, food production, pharmaceuticals. |

| Deionisation (DI) | Chemical ion exchange process. | Electrically charged ions (minerals like calcium, sodium, chloride). | Creating ultra-pure water for labs, electronics manufacturing, and high-spec processes. |

| UV Sterilisation | Disinfects water with ultraviolet light. | Bacteria, viruses, moulds, and other microorganisms. | Final polishing step in pharmaceuticals, beverage bottling, and cosmetics. |

Now, let's break down exactly what each of these does and where they shine.

Reverse Osmosis: The Molecular Sieve

Reverse Osmosis (RO) is one of the most powerful and widely used purification methods out there. The best way to think of it is as an incredibly fine molecular sieve. In an RO system, water is pushed under high pressure against a semi-permeable membrane—a barrier with pores so tiny that only water molecules can squeeze through.

This pressure-driven separation is astonishingly effective. It physically blocks the vast majority of contaminants, leaving them behind on one side of the membrane while pure water collects on the other. An RO system is the go-to workhorse for removing a huge spectrum of impurities.

- What it removes: Dissolved salts (like sodium and chloride), minerals (calcium, magnesium), heavy metals (lead, arsenic), and larger organic molecules. It can remove up to 99.9% of these contaminants.

- Where it's used: Desalination, treating boiler feed water, pharmaceutical manufacturing, and in food and beverage production where mineral content needs tight control.

- What it needs: RO requires serious pressure to work, which means it uses a fair bit of energy. It also depends on good pre-treatment to stop the membrane from getting clogged or damaged by things like sediment and chlorine.

Deionisation: The Purity Magnet

While RO is fantastic at removing most dissolved solids, some applications demand an even higher level of purity. That's where Deionisation (DI) steps in. A great analogy for DI is a set of powerful magnets, specifically designed to attract and pull electrically charged particles (ions) out of the water.

DI systems use special resin beds packed with tiny beads that carry either a positive or a negative charge. As water flows through, the charged mineral ions "stick" to the oppositely charged resin, swapping places with harmless hydrogen and hydroxyl ions. These then combine to form pure H₂O.

The result is exceptionally pure water, often called demineralised or ultra-pure water. To get a better sense of the mechanics, you can discover more about https://24purewater.co.uk/how-it-works/.

Deionisation isn’t about filtering particles. It's a chemical process that strips water of nearly all its ionic mineral content, producing a final product with extremely low electrical conductivity.

Ultraviolet Sterilisation: The Microbial Neutraliser

Finally, even water that’s free from minerals and solids can still hide invisible threats like bacteria, viruses, and moulds. Ultraviolet (UV) Sterilisation is the non-chemical answer to this biological contamination. It works like concentrated sunlight, using a specific wavelength of UV light (UV-C) to scramble the DNA of microorganisms.

This exposure makes it impossible for them to reproduce or cause any harm. Water simply flows through a chamber containing a UV lamp, and any living organisms are instantly neutralised as they pass by.

UV sterilisation is often the critical last step in a purification process, acting as a final guard to ensure microbial safety without adding a single chemical to the water. To delve deeper into specific purification methods, you can explore the various types of highly effective water filtration systems available.

- What it neutralises: Bacteria, viruses, algae, moulds, and other pathogens.

- Where it's used: Pharmaceutical production, beverage bottling, cosmetics manufacturing, and any process where biological stability is non-negotiable.

- What it needs: UV light can't penetrate murky water; suspended solids can create shadows that shield microorganisms. For that reason, it’s almost always used after other filtration methods, like RO or sediment filtration, have cleared the way.

The Business Case for Investing in Pure Water

Beyond the complex engineering and technical specs, there’s a simple commercial truth: putting your money into a robust industrial water purification system is one of the smartest financial moves you can make. This isn't just about getting clean water; it's about driving real, measurable value that hits your bottom line. When you see how pure water protects your assets, guarantees quality, and cuts down on risk, the return on investment becomes crystal clear.

Many businesses completely underestimate the hidden costs of using untreated or poorly treated water. These expenses sneak up on you as frequent repairs, mysterious production flaws, and wasted resources, slowly chipping away at your profits. A strategic investment in water purification flips the script from reactive firefighting to proactive value creation.

Enhance Product Consistency and Quality

For countless UK industries, water isn't just a utility—it's a primary ingredient. Whether it's going into a pharmaceutical formula, a food and beverage recipe, or a chemical mix, the quality of that water dictates the quality of your final product. Simple as that.

Untreated water is a lottery. It contains a variable cocktail of dissolved minerals, organic compounds, and other contaminants. These impurities can throw off chemical reactions, ruin the taste and look of a product, or even make it unsafe. By using purified water, you create a stable, reliable baseline, ensuring every single batch is exactly like the last.

- Food and Beverage: It guarantees the flavour profile of your craft beer or soft drink is identical, batch after batch. No surprises.

- Pharmaceuticals: It stops mineral ions from interfering with sensitive chemical compounds, ensuring drug efficacy and safety are never compromised.

- Manufacturing: It gets rid of mineral deposits that can ruin paint finishes, coatings, and other surface treatments, dramatically cutting down on defects.

Protect Expensive Equipment and Slash Downtime

One of the most immediate and significant wins from a new water purification system is the protection it offers your capital equipment. The minerals lurking in mains water, especially calcium and magnesium, are notorious for causing incredibly expensive damage over time.

These minerals drop out of the water and form limescale, that hard, crusty deposit that clogs pipes, smothers heating elements, and insulates heat exchangers. This build-up forces your machinery to work harder, guzzle more energy, and eventually, fail long before its time.

A mere 1.5 mm of limescale build-up can slash a boiler's heat transfer efficiency by up to 12%. That translates directly into higher fuel bills and more strain on your equipment. Investing in purified water is like taking out an insurance policy against this silent, costly killer.

By removing these scale-forming minerals right at the source, a purification system stops the damage before it even starts. The result? A massive reduction in unplanned downtime, fewer panicked calls for emergency maintenance, and a much longer, more productive life for your most valuable assets. Think of it as preventative care for your entire water-fed infrastructure.

Ensure Regulatory Compliance and Avoid Costly Fines

Finally, operating in the UK means you're up against some of the world's tightest health, safety, and environmental regulations. These standards govern everything from the purity of water used in your processes to the contaminants in the wastewater you discharge.

Getting it wrong can have serious consequences. We're talking about hefty financial penalties, production shutdowns ordered by bodies like the Environment Agency, and long-lasting reputational damage that can destroy customer trust.

A professionally specified industrial water purification system is designed not just for operational efficiency but for your peace of mind. It ensures your process water meets all the necessary purity standards and that your effluent is treated properly before release. This keeps you compliant, protects you from legal and financial risks, and turns a regulatory headache into a clear statement of your corporate responsibility.

Where It All Comes Together: Real-World Applications Across the UK

You can truly grasp the power of industrial water purification when you see it in action. All across the UK, from sterile labs to busy food factories, highly purified water is the unsung hero. It's the one thing that connects seemingly unrelated industries, even though each one has its own exacting standards for what "clean" really means.

The need for this technology is only growing. With increasing pressure on our natural water sources from industry and urbanisation, having a reliable way to purify water is becoming less of a choice and more of a necessity. In fact, the UK's water purifier market is projected to grow by an impressive 8% each year between 2025 and 2031. This surge is a direct response to rising pollution and the ongoing challenges of an ageing public water infrastructure.

Looking at how different sectors use this technology shows why a generic, off-the-shelf solution rarely cuts it.

Pharmaceuticals and Life Sciences

In pharmaceuticals, water isn't just for cleaning; it's a fundamental ingredient. The tiniest impurity—a stray microbe or a trace mineral—can ruin an entire batch of medicine, putting patient safety at risk and costing millions. This is why the industry demands ultra-pure water (UPW), which is about as close to pure H₂O as you can get.

This uncompromising level of purity is essential for:

- Making sterile products: Think of injectables, vaccines, and IV drips. There's zero tolerance for microorganisms or the toxins they produce.

- Lab work and research: When you're running tests, you need to know your results are accurate. Impure water can skew outcomes and make experiments impossible to replicate.

- Cleaning and sterilising equipment: To prevent any contamination between different product runs, everything has to be cleaned with water that won't leave any residue behind.

To hit these standards, pharmaceutical plants use a sophisticated, multi-step process. They'll often chain together reverse osmosis, deionisation, and UV sterilisation systems to systematically remove every possible contaminant.

Food and Beverage Production

For anyone making food or drinks, the quality of their water directly impacts the final product's taste, look, shelf life, and, most importantly, its safety. For example, the mineral content in water can completely change the flavour of a craft beer or a popular soft drink. Any hint of microbial contamination is a serious public health hazard.

This is why consistent water quality is a cornerstone of brand integrity. Purification systems take the guesswork out of using mains water, which can vary from day to day and place to place.

Purified water is the secret ingredient for quality control. It guarantees that a drink made in Manchester tastes exactly the same as one made in Bristol, protecting a brand's reputation and keeping customers happy.

You'll find purified water being used for:

- As an ingredient: It’s a key component in everything from bread and sauces to cordials and spirits.

- Washing and processing: Used to clean fresh produce without adding any new contaminants.

- Clean-in-place (CIP) systems: For rinsing and sanitising production lines and tanks between batches.

Electronics and Microchip Manufacturing

The world of electronics is a world of miniatures. When you're making microchips and semiconductors, even a microscopic dust particle can cause a major failure. Water is used constantly to rinse and clean silicon wafers at multiple stages of production.

If that rinsing water contains any dissolved salts, ions, or tiny particles, it can leave a residue that interferes with the delicate electrical circuits, causing short circuits and destroying the component. This is where ultra-pure water becomes absolutely critical. The mind-boggling level of purity needed is one of the key reasons why there are several important industries that use ultrapure water.

The aim is to create water so pure that it acts as a perfect cleaning agent, leaving absolutely nothing behind. This is usually done with an advanced setup combining reverse osmosis, powerful deionisation systems, and ultrafiltration to protect billions of pounds worth of high-tech components.

Choosing the Right Water Purification System for Your Facility

Picking the right industrial water purification system is one of those big decisions that can seriously impact your bottom line. It’s not just about buying a piece of kit; it's an investment in your operational efficiency, the quality of your final product, and your long-term running costs. It’s easy to get drawn to the biggest, most powerful system, but the real goal is to find the one that’s a perfect fit for what you actually do. A methodical approach here will save you a world of headaches and expensive mistakes down the line.

Think of it like getting a prescription from a doctor. You wouldn't want them guessing what’s wrong, would you? You’d expect a proper diagnosis first. It’s the same with water treatment. Rushing this foundational step is a sure-fire way to end up with a system that’s over-engineered and costly, or even worse, one that simply can't do the job you need it to.

It All Starts with a Proper Water Analysis

First things first: you absolutely have to get a professional analysis of your source water. This is non-negotiable. Whether you’re pulling from the mains, a borehole, or another source, you need a clear picture of what you’re dealing with. This analysis is your roadmap, showing you exactly which contaminants need to be tackled.

And we’re not just talking about obvious stuff like silt or grit. A detailed report gives you the critical data points:

- Total Dissolved Solids (TDS): This tells you the total amount of minerals, salts, and metals dissolved in the water.

- Hardness: Specifically, how much calcium and magnesium is present? These are the primary culprits behind limescale build-up that can cripple equipment.

- pH Level: Is your water acidic or alkaline? This has a huge impact on corrosion rates for your pipework and machinery.

- Microbiological Content: Are there any bacteria, viruses, or other nasty bugs lurking in there?

- Specific Contaminants: Things like iron, manganese, or chlorides might be present in small amounts but can cause big problems for certain industrial processes.

Without this data, you’re flying blind.

Figure Out Your Operational Needs

Once you know what's in your water, the next step is to nail down what your operation actually needs from it. This means answering some pretty specific questions about how your facility runs day-to-day. A system that’s too small will cause bottlenecks and bring production to a grinding halt, while an oversized one is just a waste of capital and energy.

Be realistic and consider these factors:

- Required Flow Rate: How much purified water do you get through per hour or per day? Don't forget to plan for peak demand – that’s when you’ll really feel the pressure.

- Purity Level: How clean does the water need to be? The standard for boiler feed water is a world away from the ultra-pure water required for manufacturing semiconductors.

- Capacity and Storage: Do you need a constant, on-demand supply, or can you store treated water in tanks and draw from it as needed?

A word of advice: always think about the total cost of ownership. The upfront price is just the beginning. A system that looks cheap initially can quickly become a money pit if it guzzles energy or needs constant maintenance.

Calculate the Total Cost of Ownership

A savvy decision always looks beyond the initial price tag. The total cost of ownership (TCO) gives you a far more accurate picture of what the system will cost you over its entire life. When you're getting quotes from suppliers, make sure you press them for a full breakdown of all the ongoing expenses.

Your TCO calculation should really cover three main areas:

- Initial Capital Investment: This is the purchase price, but also includes costs for design work, any customisation, and the final installation.

- Running Costs: Think electricity to run pumps and controls, plus the cost of the raw water itself. Here in the UK, that’s always going to be in pounds sterling (£).

- Ongoing Maintenance: You need to budget for consumables like replacement filters, membranes, and deionisation resins. Don’t forget to factor in any scheduled service contracts, too.

By following these steps, you’re no longer guessing. You’re making a data-driven decision that ensures your new industrial water purification system becomes a valuable, reliable asset for your business for years to come.

Keeping Your System Running Smoothly: A Guide to Long-Term Performance

Getting a new industrial water purification system installed is a major step, but it's really just the beginning of the journey. Think of it like a high-performance engine; you wouldn’t just run it into the ground without regular servicing. Proper, proactive maintenance is absolutely key to protecting that investment, getting the most out of its lifespan, and ensuring the water quality you rely on stays consistently high.

If you let maintenance slide, you’re opening the door to a whole host of problems. You'll see efficiency plummet, energy bills creep up, and you’ll be at a much higher risk of a sudden, costly breakdown that could halt production. Even worse, a system that isn't looked after can start failing, allowing contaminants back into your water. This not only threatens your product quality but can create genuine safety hazards. A structured maintenance plan isn't just a good idea—it's essential.

Your Practical Maintenance Checklist

The secret to effective system care is routine. By building a clear schedule, you ensure that small issues are spotted and fixed long before they have a chance to become catastrophic failures.

Here’s a good starting point:

- Regular Filter Changes: Your pre-filters and post-filters are the gatekeepers. When they get clogged, the whole system has to work harder, and contaminants can slip through. Stick to the manufacturer's replacement schedule religiously.

- Membrane Care (for RO Systems): Over time, reverse osmosis membranes get fouled with build-up, which kills their efficiency. They need to be cleaned periodically, and regular performance monitoring will tell you exactly when it's time.

- Keep Instruments Calibrated: The sensors and meters tracking things like pH and TDS are your eyes on the system. If they aren't regularly calibrated, you can't trust their readings, which is a recipe for disaster.

- Invest in Team Training: Make sure the operators running the system daily know what they're looking at. They should be able to perform basic checks, recognise warning signs, and understand what the system is supposed to be doing.

Think of a maintenance log as your system's medical chart. It should track performance over time, note every service and part replacement, and provide a goldmine of data for troubleshooting. It creates a history and keeps everything accountable.

This hands-on approach is more important than ever, especially when you look at the bigger picture of the UK water industry. For context, Thames Water alone supplied roughly 2.6 billion litres of drinking water every day in 2022/23. The entire sector is under intense pressure to manage water responsibly, making robust, in-house purification and maintenance a critical piece of the puzzle.

To get the best out of these systems, many facilities also focus on the control mechanisms that keep everything stable and efficient. In fact, understanding how to be smart with energy use is a huge part of long-term reliability. Learning about maximizing energy efficiency with PID controllers is a great way to see how precise control can optimise performance and cut down on operational costs.

Frequently Asked Questions

When you're looking into industrial water purification systems, it's natural for questions to pop up. Getting the right technology for your specific business needs is a big decision, so let's clear up some of the most common queries.

How Is Industrial Water Purification Different from Drinking Water Treatment?

The main difference is the end game. Treating drinking water is all about making it safe for us to consume. This means removing pathogens and specific chemicals to meet strict UK health standards.

Industrial purification, on the other hand, is about preparing water for a specific job. It often means stripping out minerals and dissolved solids that are harmless to drink but could wreak havoc on sensitive machinery or ruin a product. The level of purity required is often far, far higher and much more specialised.

What Is the Lifespan of an Industrial Purification System?

That really depends on the technology you choose, the quality of your incoming water, and, most importantly, how well you look after it.

A well-maintained reverse osmosis system, for instance, can serve you well for 15-20 years. Of course, you'll need to replace key parts like the membranes every 3-5 years. The biggest factor in getting the most out of your investment is always going to be consistent, proactive maintenance.

Can a Purification System Be Customised for My Needs?

Not only can it be, but it absolutely should be. A one-size-fits-all approach just doesn't cut it in this field. Every facility has its own unique mix of source water quality, purity targets, and operational scale.

A good provider will always kick things off with a detailed analysis of your water. From there, they'll work with you to design a system that fits your requirements perfectly, making sure it’s both efficient and budget-friendly.

It's crucial to realise that the right system isn't just about the technology itself, but how it's integrated into your specific process. A tailored solution prevents over-engineering and ensures you aren't paying for purification capabilities you don't need.

For more in-depth answers, feel free to explore our comprehensive industrial water purification FAQs, which dive into a wider range of technical and practical topics.

Ready to secure a reliable source of ultra-pure water for your business needs? With 24 Pure Water, you can access deionised water on demand, 24/7, across our nationwide network of self-service filling stations. Visit us at https://24purewater.co.uk to find your nearest station and simplify your workflow today.