A pure water system is essentially a setup that strips out almost all of the dissolved solids and other impurities you'd normally find in tap water, leaving you with exceptionally clean H₂O. Your standard UK tap water is perfectly safe to drink, of course, but it’s full of minerals and trace chemicals from the treatment process. For many jobs, from window cleaning to scientific research, those substances can be a real problem.

What Makes Pure Water Different from Tap Water

Most of us in the UK take for granted that we can turn on the tap and get high-quality drinking water. But 'safe' and 'pure' mean two completely different things when we talk about water quality.

Think of it like this: tap water is a bit like a busy city street. It's functional and gets the job done, but it’s also crowded with other things – cars, bikes, pedestrians. Pure water, on the other hand, is like an empty, freshly laid motorway. There’s nothing on it but the road itself.

That difference all comes down to Total Dissolved Solids (TDS). These are the tiny mineral and salt particles left behind when water evaporates. While they're harmless for us to drink, they’re the culprits behind some very common frustrations:

- White Spots: Ever washed your car or windows only to see them dry covered in stubborn white spots and streaks? That's TDS.

- Limescale Build-up: That chalky scale inside your kettle or steam iron is just a build-up of these minerals, which wrecks appliances over time.

- Inaccurate Results: In highly sensitive settings like a science lab or even a specialist aquarium, these dissolved minerals can throw chemical balances completely out of whack.

Pure water systems are designed specifically to eliminate these dissolved solids. They take water from a state that's safe to drink to one that's incredibly clean for specialist tasks. To dive deeper into this, check out our guide on why ultrapure water is not your drinking water.

The Journey to Purity

So, how do we get there? The journey to purity in most pure water systems relies on two main technologies working in tandem: Reverse Osmosis (RO) and Deionisation (DI).

First, Reverse Osmosis acts as an extremely fine filter. It forces water through a special membrane that physically blocks the vast majority of minerals from passing through. Then comes Deionisation, which you can think of as the final 'polishing' stage. It uses clever resin beads that work like tiny magnets, attracting and grabbing any last mineral ions that the RO filter might have missed.

When used together, these two processes strip away almost everything that isn't pure H₂O, producing water of an exceptionally high standard.

How UK Water History Shaped the Need for Purification

The UK’s long history of water management actually plays a big part in why we need these systems today. A massive shift happened back in 1989 when water services in England and Wales were privatised.

Before then, the network was quite fragmented. Privatisation created large regional water companies and brought in regulators like the Drinking Water Inspectorate (DWI) and Ofwat to set and enforce quality standards. While this led to huge investments and better drinking water for everyone, it also put a spotlight on the unique mineral content of water in different regions.

This new awareness really drove home the need for specialised purification for professional and industrial jobs, pushing the development of the advanced technologies we now rely on.

So, How Does It All Actually Work?

The idea of turning regular tap water into something so incredibly pure sounds complicated, almost like magic. But when you break it down, the process behind pure water systems is really quite clever and easy to grasp. It’s not one single action, but a sequence of stages, each designed to tackle a different kind of impurity.

Think of it as an assembly line for water. Each stop on the line has a specific job, working together to strip away contaminants until all that’s left is pure H₂O.

The Heavy Lifter: Reverse Osmosis

The first and most critical stage for any high-quality system is Reverse Osmosis (RO). This is the powerhouse of the operation, tasked with removing the overwhelming majority of minerals, salts, and other dissolved solids from the water.

Imagine trying to push water through a filter so fine that only the water molecules themselves can get through. That’s essentially what an RO membrane does. Water is forced under high pressure against this special membrane, which has pores measuring around 0.0001 microns—impossibly small.

This pressure reverses the natural process of osmosis, pushing pure water molecules across the membrane while leaving everything else behind. Minerals like calcium and magnesium, salts, and even most bacteria are blocked and simply flushed away as wastewater. The RO stage alone is so effective it can remove up to 99% of all total dissolved solids (TDS). It does the real grunt work.

The Polishing Touch: Deionisation

After the RO stage, the water is already remarkably clean. But for applications where you need a flawless, spot-free finish—like professional window cleaning—you need to go one step further. That’s where Deionisation (DI) comes into play.

If RO is the heavy lifter, think of DI as the final polisher. The water, now mostly pure, flows through a tank filled with a special ion-exchange resin. These tiny resin beads are like powerful magnets, specifically designed to attract and trap any lingering mineral ions that squeaked past the RO membrane.

The deionisation process cleverly swaps the last remaining mineral ions (like calcium) for hydrogen and hydroxyl ions. These two then combine to form a pure water molecule (H₂O), leaving absolutely nothing behind that could cause streaks or spots.

This final touch is what gets the water from very good to perfectly pure, bringing the TDS reading down to an ideal 0 parts per million (PPM).

The Unsung Hero: Pre-Filtration

Before the water even gets to the high-tech RO and DI stages, it has to pass through a couple of crucial pre-filters. These are the unsung heroes of the whole system, protecting the more sensitive and expensive components from damage.

There are usually two key types of pre-filters:

- Sediment Filters: Their job is simple: catch the big stuff. Sand, rust, silt, and any other bits of debris are trapped here. This prevents the delicate RO membrane from getting clogged up, which would drastically reduce its lifespan and performance.

- Carbon Filters: These use activated carbon to absorb chemicals, most importantly chlorine. Chlorine is great for disinfecting tap water, but it will quickly degrade and destroy an RO membrane. The carbon filter acts like a sponge, soaking it up before it can do any harm.

By prepping the water this way, the whole system runs smoother and lasts much longer. Each stage has a vital role, and seeing how they work together makes the whole process make sense. To get an even deeper look, you can learn more about how our pure water systems work and the technology we use.

Comparing the Main Types of Pure Water Systems

Trying to pick the right pure water system can feel a bit overwhelming, but it really comes down to a simple question: what do you need the water for? Each system is designed for a specific job, and understanding the main technologies—Reverse Osmosis (RO), Deionisation (DI), and combined RO/DI units—is the key to finding the perfect match.

Think of it like choosing a tool for a job. You wouldn't use a sledgehammer to hang a picture frame, and you wouldn't use a tiny screwdriver to break up concrete. In the same way, the best pure water system depends entirely on your needs, balancing performance, running costs, and the level of purity required.

Reverse Osmosis: The Dependable Workhorse

A standalone Reverse Osmosis (RO) system is the real workhorse of water purification. Its job is to do the heavy lifting, stripping out the vast majority of impurities from your tap water. We're talking about removing up to 99% of all Total Dissolved Solids (TDS), and it does this at a remarkably low cost per litre. It’s the perfect all-rounder for many professional applications.

For jobs like general window cleaning or car valeting, where you need a great finish but aren't aiming for microscopic perfection, an RO system is often more than enough. It gets rid of the minerals that cause the most obvious spotting and streaks, making it a brilliant, cost-effective solution for anyone using large volumes of water every day. Its biggest strength is bulk purification without the eye-watering consumable costs you get with other methods.

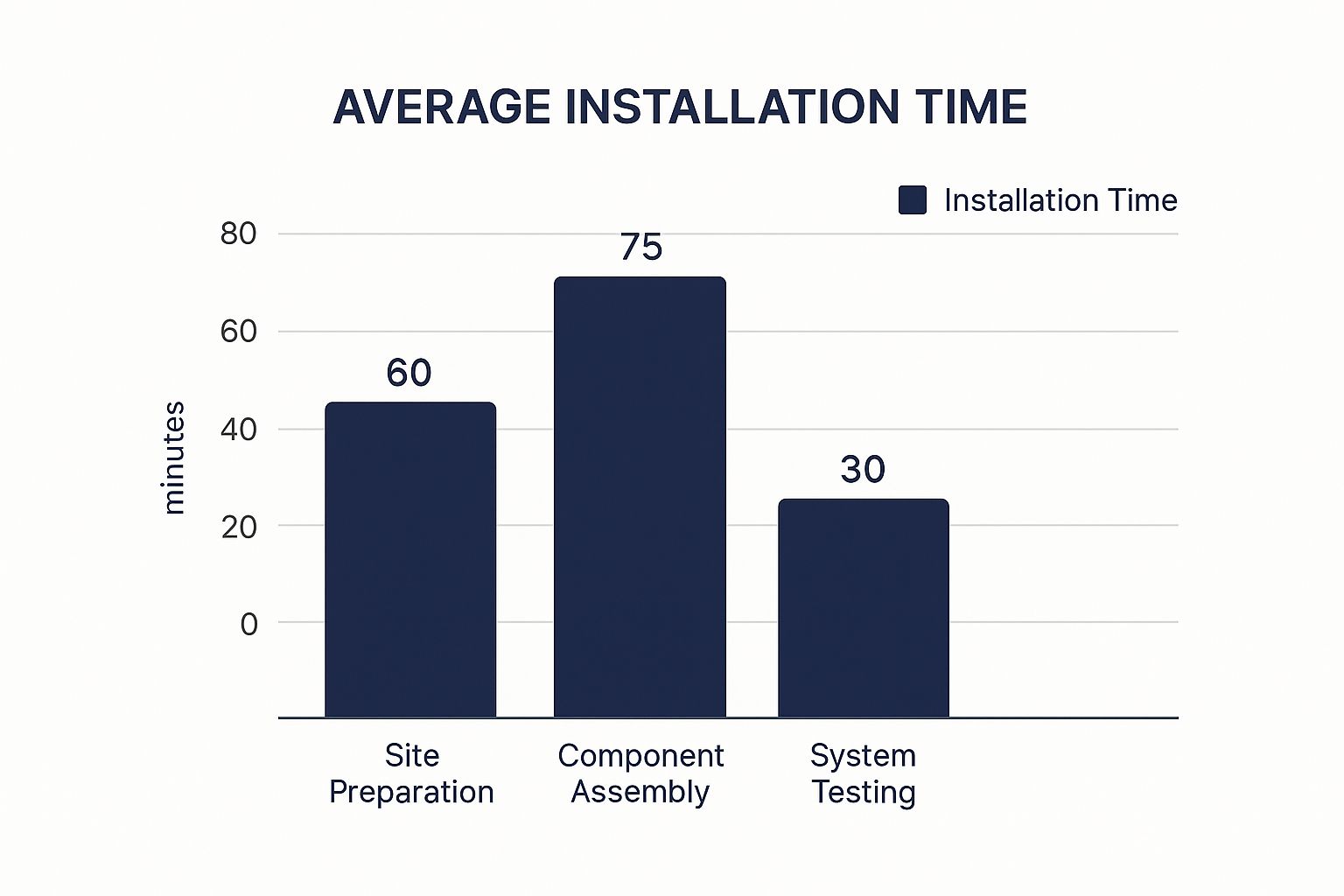

This image shows just how the setup time for these systems typically breaks down, from the first checks to the final tests.

As you can see, putting the actual components together takes the most time, which really underlines how important good planning and clear instructions are from the get-go.

Deionisation: The Flawless Finisher

If RO is the workhorse, then a Deionisation (DI) system is the specialist finisher, the master craftsperson. This technology has one goal: to achieve the absolute highest level of water purity possible. It uses special ion-exchange resin beads that grab onto every last mineral ion, polishing the water until it reaches a perfect TDS reading of 0 parts per million (PPM).

This level of purity is essential for any job that demands a completely flawless, spot-free finish. Think high-end car detailing, cleaning sensitive solar panels, or preparing solutions in a laboratory. Here, even the tiniest mineral deposit can ruin the result. But, perfection has its price. Using a DI-only system in a hard water area can get incredibly expensive because the resin gets used up very quickly, meaning you're constantly paying for replacements.

That’s why you’ll rarely see DI used by itself for purifying large amounts of water. It shines brightest—and is far more economical—when it’s used as the final polishing step after an RO system has already done the bulk of the work.

Combined RO and DI: The Ultimate Solution

So, what if you want the best of both worlds? That's where a combined RO/DI system comes in. This setup creates the ultimate purification partnership, playing to the strengths of each technology for a super-efficient and cost-effective process. The RO unit acts as the first line of defence, stripping out 95-99% of the TDS.

This pre-cleaned water then flows into the DI vessel for its final polish. Because the DI resin is now only dealing with the tiny fraction of minerals the RO membrane left behind, it lasts so much longer. This drastically cuts your running costs while still guaranteeing you get that ultra-pure, 0 PPM water every single time. It’s no surprise that this combined approach is the industry standard for professionals who need consistently perfect water without constantly worrying about the cost of consumables.

Comparison of Water Purification Technologies

To make the choice clearer, let's break down how these technologies stack up against each other. This table gives a quick overview of what each system does best, helping you pinpoint the right solution for your specific needs.

| Technology Type | Primary Function | Purity Level (TDS) | Typical Applications | Pros | Cons |

|---|---|---|---|---|---|

| Reverse Osmosis (RO) | Bulk removal of minerals and contaminants | Reduces TDS by 95-99% | General window cleaning, car valeting, pre-treatment | Low running costs, removes a wide range of impurities | Doesn't achieve 0 PPM, produces wastewater |

| Deionisation (DI) | Polishing water to remove all remaining ions | Achieves 0 PPM | High-end car detailing, solar panel cleaning, laboratories | Produces the purest water, simple to operate | High consumable cost (resin), ineffective on its own in hard water |

| Combined RO/DI | Complete, multi-stage purification | Achieves a consistent 0 PPM | Professional window cleaning, critical cleaning processes | Delivers ultimate purity, highly cost-effective long-term | Higher initial investment, more complex setup |

Ultimately, the right system is the one that meets your quality demands without unnecessary expense. For bulk, cost-effective cleaning, RO is a strong contender. For absolute perfection, especially after pre-treatment, DI is essential. And for the professional who needs both quality and efficiency, the combined RO/DI system is the undisputed champion.

What Pure Water Actually Does for You in the Real World

It’s one thing to get your head around the science of pure water systems, but it’s when you see the results in person that it all clicks. Forget the technical jargon for a moment. The benefits of using mineral-free water are practical, often immediate, and genuinely make a difference in all sorts of places, from professional cleaning jobs to keeping things running smoothly at home.

The idea behind it is incredibly simple. When you strip out all the dissolved minerals that leave behind spots, streaks, and limescale, you get a much better result. For anyone in a trade, this means better quality work, happier clients, and a business that people trust. It’s the secret sauce for a perfect finish.

A Flawless Finish Every Time

Ask any professional window cleaner or car detailer, and they'll tell you pure water isn't a "nice-to-have"—it's an essential part of their toolkit. When you use regular tap water, it evaporates and leaves behind a chalky film of minerals like calcium and magnesium. That's what causes those annoying white spots and streaks on glass and paintwork.

Pure water solves this completely. Because it has no dissolved solids, it dries to a crystal-clear, totally streak-free finish. There’s no need to go back over it with a squeegee or a cloth. Not only does this look infinitely better, but it also makes the job much, much faster. More jobs done in a day means a healthier bottom line.

In a competitive field, that level of quality really matters.

A flawless, spot-free finish isn’t a luxury anymore—it’s the standard clients have come to expect. Pure water systems give professionals the power to deliver that exceptional quality, job after job, protecting their reputation and keeping customers coming back.

Protecting Your Gear and Getting Things Right

The benefits go well beyond just looking good. In many situations, the minerals lurking in tap water can cause real damage and operational headaches over time.

- Longer-Lasting Appliances: At home, think about your steam iron, humidifier, or coffee machine. Using pure water stops limescale from building up inside them. That crusty scale makes them work harder, use more energy, and eventually, just gives up the ghost.

- Accuracy in the Lab: For scientists and medical staff, even the tiniest impurity can throw off a sensitive experiment or a sterilisation cycle. Pure water is non-negotiable for mixing precise chemical solutions and ensuring results are accurate and can be replicated.

- Specialist Hobbies: If you've ever kept an aquarium, especially with delicate marine fish, you'll know that tap water can be a minefield of harmful minerals and chemicals. Pure water gives enthusiasts total control over the tank's chemistry, creating a stable, healthy world for their aquatic life.

The Bigger Picture: Cost and Quality

The push for better water isn't just a niche concern. Since the water industry was privatised back in 1989, companies across England and Wales have poured around £50 billion into upgrading infrastructure to meet tough quality standards. While this has certainly improved the tap water for all of us, it shows just how complex and expensive large-scale water management is. It also makes having your own purification system for specific needs a much more practical and effective solution.

At the end of the day, whether you're a professional who obsesses over quality or a homeowner wanting to protect your appliances, the argument for using pure water is a strong one. It saves time, cuts down on repair costs, and simply delivers a better result, every time. To see just how wide-ranging its uses are, check out our article on the key industries that use ultra-pure water.

How to Choose the Right System for You

Ready to take the plunge and invest in a pure water system? It can feel a bit daunting, but picking the right setup doesn't have to be a headache. It really just comes down to asking a few key questions to find that sweet spot between performance, cost, and practicality for what you actually need.

Think of it as matching the right tool to the job. You'll need to look at the water coming out of your tap, figure out how pure you need it to be, and get a rough idea of your daily usage. Get this right from the get-go, and you'll end up with a system that not only does the job well but won't cost a fortune to run down the line.

Assess Your Local Water Quality

First things first: you have to know what you’re working with. The quality of your local tap water is the single biggest factor that will steer your decision, especially when it comes to running costs.

The key measurement here is water hardness, which is just the amount of dissolved minerals like calcium and magnesium floating around. The easiest way to check is by visiting your local water supplier's website – they usually have detailed quality reports. For a quick and dirty check, you can grab a simple TDS (Total Dissolved Solids) meter online for a few quid. It'll give you an instant reading in parts per million (PPM).

A high TDS reading – say, anything over 250 PPM – means you've got hard water. In these areas, trying to use a Deionisation (DI) system on its own would be financial suicide. The resin would get used up in no time. This is where a Reverse Osmosis (RO) system becomes essential as the first stage to do all the heavy lifting.

Define Your Required Purity Level

Next, be honest about how pure your water really needs to be. Chasing that perfect 0 PPM reading isn't always necessary, and it can add cost you don't need to spend. The job itself dictates the level of purity required.

Let's look at a few common examples:

- General Cleaning & Car Valeting: For a lot of cleaning jobs, an RO system on its own is more than enough. It'll strip out 95-99% of the gunk, which gets rid of the minerals that cause the most noticeable spotting.

- Professional Window Cleaning & Detailing: This is where perfection matters. For that flawless, streak-free finish that keeps customers happy, you absolutely need to hit 0 PPM. A combined RO/DI system is the industry standard for a reason – it guarantees total purity.

- Laboratories & Aquariums: In highly sensitive environments, there's no room for error. Precise chemical balances are everything, making ultra-pure water a must. A full-blown RO/DI setup is the only option here.

Matching the purity level to the task means you won't over-invest in a system that's overkill for your needs.

Calculate Your Water Consumption

So, how much pure water are you actually going to get through in a day or a week? This will tell you what size and capacity of system to go for. A small, portable unit might be fine for a hobbyist, but a professional cleaning business will need something that can churn out hundreds of litres a day without breaking a sweat.

System capacity is usually measured in GPD (gallons per day) or litres per hour. If you underestimate, you'll spend a lot of frustrating time waiting for your tank to fill up. Overestimate, and you've spent more than you needed to upfront. A good rule of thumb is to work out your average daily use and then pick a system with a little extra capacity to handle those unexpectedly busy days.

Finally, don't just look at the price tag. The total cost of ownership is what really matters. A cheap, DI-only system might look tempting, but if you're in a hard water area, the constant cost of new resin will quickly wipe out any initial savings. The smart move is to balance that upfront investment against the long-term running costs for filters and resin. That’s how you find a solution that’s genuinely economical.

Keeping Your System Running Perfectly

You've invested in a pure water system, and just like any high-performance piece of kit, it needs a bit of regular care to keep delivering the goods. Think of it less as a chore and more as protecting your investment. Good maintenance is the secret to getting years of service from your equipment and consistently pure water.

The good news is, you don't need to be a mechanical whizz to look after your system. A few simple, routine checks are all it takes to head off common problems, save a fortune on repairs, and guarantee you get that perfect, ultra-pure water you need, every single time.

Essential Routine Checks and Monitoring

If you have one tool in your maintenance kit, make it a Total Dissolved Solids (TDS) metre. This little handheld device is your system's health monitor, giving you an instant reading of water purity in parts per million (PPM).

Make a habit of checking your water quality regularly. It's the best way to stay ahead of any issues. A sudden jump or even a slow creep upwards in the TDS reading is the clearest signal you can get that a component, like your DI resin or RO membrane, is getting tired and needs replacing.

Your TDS metre is basically the fuel gauge for your system. When you see the reading start to climb from your target of 0 PPM, it's a clear sign it's time to 'refuel' by changing a filter or swapping out the resin.

Understanding Replacement Schedules

While a TDS metre tells you precisely when to act, it helps to have a rough idea of how long the core parts of your system should last. Of course, these are just guidelines – how often you use it and the hardness of your local water will play a big part.

- Pre-filters (Sediment and Carbon): These are your system's bodyguards, protecting the more delicate and expensive components from grit and chlorine. Plan to replace them every 3-6 months to keep everything flowing smoothly.

- Reverse Osmosis (RO) Membrane: This is the real workhorse. If you're diligent about changing your pre-filters, a quality RO membrane can last for 2-3 years, sometimes even longer. A noticeable drop in water flow is the classic sign it's on its way out.

- Deionisation (DI) Resin: This is the final polishing stage. How long it lasts is completely down to how much work the RO membrane leaves for it to do. As soon as your TDS reading consistently goes above 0 PPM, it's time for a fresh batch.

Simple Troubleshooting for Common Issues

Even the best-maintained systems have an off day. Knowing how to spot and fix the most common hiccups can save you a lot of time and the cost of calling in a pro.

Here are a few things to look out for:

- Leaks: Nine times out of ten, a small drip is just a loose connection. Before you panic, give all the fittings a quick check and a gentle tighten, especially after you've just changed a filter.

- Slow Production: This almost always points to either a clogged pre-filter or a failing RO membrane. Always start by changing the pre-filters – it's the most common culprit and the cheapest fix.

- High TDS Reading: If the purity of your final water drops, your DI resin is the first place to look. It's almost certainly the component that needs replacing.

Staying on top of maintenance is key, but it's also worth remembering what these systems are up against. In 2023, English water companies discharged untreated sewage over 460,000 times, which really drives home the challenges facing the UK's water infrastructure. It’s a stark reminder of why robust, reliable purification is more important than ever. You can learn more about water use and challenges in the UK on Statista.com.

Frequently Asked Questions

It’s completely normal to have questions when you’re looking into pure water systems, especially when trying to figure out the best setup for your needs. We get asked a lot of great questions, so we’ve put together some straightforward answers to the most common ones we hear from professionals across the UK.

Getting these basics right helps clear up why making the switch from regular tap water to a professionally purified solution can make such a massive difference.

How Is Pure Water Different From UK Tap Water?

While the tap water across the UK is perfectly safe to drink, it’s far from pure. It contains a whole host of dissolved minerals, like calcium and magnesium, as well as additives from the treatment process, such as chlorine.

These are the very things that cause stubborn limescale in your kettle and leave those frustrating white spots on windows and car paintwork when the water evaporates.

A pure water system is designed to take all of that out. The goal is to remove virtually all of these total dissolved solids (TDS), leaving you with nothing but H₂O. This is what guarantees a streak-free finish on glass, prevents scale from damaging expensive equipment, and meets the strict standards for scientific and manufacturing work where any contaminant could spell disaster.

Do I Need Both Reverse Osmosis and Deionisation?

This is a brilliant question, and the honest answer is: it depends entirely on what you're trying to achieve.

For many professional jobs, like most domestic window cleaning, a good Reverse Osmosis (RO) system gets you most of the way there. It effectively removes the bulk of impurities and can be more than enough to get great results.

However, if you're aiming for that 100% spot-free finish every single time, or if you're working in a lab that demands the absolute highest grade of water, then adding a Deionisation (DI) system is essential. The best way to think about it is that RO does the heavy lifting, while DI acts as the final 'polishing' stage to catch anything the RO membrane might have missed. For a deeper dive, our pure water FAQs page has even more detail.

Using RO and DI together isn't just about achieving ultimate purity. It's also the most economical approach for high-volume users. The RO system protects the DI resin by removing most of the contaminants, making your expensive resin last much, much longer.

How Often Must I Replace Filters and Resin?

There’s no single answer here because it all comes down to two key things: how much water you use and how hard your local tap water is.

If you’re in a hard water area of the UK, you’ll find your pre-filters may need changing every 3-6 months to stop them from clogging and to protect the crucial RO membrane.

The DI resin is your final quality check. As soon as your TDS metre starts to creep up above your target (say, over 0-10 parts per million), it's time for a replacement. If you stay on top of your pre-filter changes, a quality RO membrane can easily last for several years.